The best RV battery for dry camping is one engineered for sustained deep discharge, wide temperature operation, and thermal safety in confined spaces.

For extended off-grid stays where shore power doesn't exist and generator runtime must be minimized, these operational constraints matter more than capacity specifications or brand popularity.

This isn't a typical battery buying decision. Dry camping stresses batteries in ways that campground use never does, and the consequences of choosing wrong become apparent miles from the nearest hookup.

Most RV battery discussions assume shore power availability. Plug in at the campground, batteries float-charge overnight, and capacity limitations rarely matter.

Dry camping eliminates that safety net. Every amp-hour comes from stored energy. Generator runtime costs fuel, creates noise, and may be restricted entirely in some locations. Solar charging depends on weather and parking orientation.

This constraint changes what "best" means. The battery that performs adequately with nightly shore power may fail completely when asked to sustain four days of refrigeration, furnace cycling, and lighting without external charging.

The selection problem becomes:

How much usable capacity can you actually access before damage occurs?

How quickly can batteries recover when charging opportunities arise?

What happens when temperatures exceed comfortable ranges?

What are the safety implications in enclosed RV compartments?

Lead-acid batteries remain common in RVs because they're inexpensive and familiar. For campground use with nightly charging, they work adequately.

For serious dry camping, their limitations become operational constraints:

50% usable capacity: Discharging below 50% causes permanent damage. A 200Ah lead-acid bank delivers only 100Ah of usable energy before requiring recharge.

Slow charge acceptance: Lead-acid batteries accept charge slowly, especially above 80% state of charge. Full recharge from generator requires hours of runtime.

Temperature sensitivity: Capacity drops significantly in cold weather. Hot weather accelerates degradation.

These characteristics mean lead-acid users either run generators frequently, cut trips short, or damage batteries through over-discharge. None of these outcomes align with why people choose dry camping.

Dry camping battery selection should prioritize operational characteristics over specifications:

Deep discharge tolerance:

The ability to access 80-100% of rated capacity without degradation directly extends trip duration. This single factor often matters more than total capacity. A 200Ah battery delivering 180Ah usable energy outperforms a 300Ah battery limited to 150Ah.

Rapid charge acceptance:

When charging opportunities arise, batteries should recover quickly. Fast charge acceptance means shorter generator runtime or better utilization of limited solar windows. The difference between 2-hour and 6-hour recharge times determines whether you run the generator during breakfast or all afternoon.

Wide temperature operation:

Dry camping locations include desert heat and mountain cold, sometimes on the same trip. Batteries should operate reliably across -20°C to +50°C without heated compartments or cooling systems.(Battery Performance in Extreme Temperatures)

Thermal safety in confined spaces:

RV battery compartments are enclosed, often near LP lines or inside living spaces. Thermal events in these locations create evacuation challenges that open installations don't face. Chemistry that resists thermal runaway provides margin that external protection alone cannot.

Lithium iron phosphate chemistry fundamentally changes the dry camping equation:

Usable capacity: 80-100% depth of discharge without damage, nearly doubling effective capacity compared to lead-acid of equal rating.

Charge acceptance: High current acceptance enables rapid recharge, reducing generator runtime from hours to under an hour for equivalent energy recovery.

Temperature range: Quality LiFePO4 operates across temperature ranges that cover four-season camping.

Weight: Significant reduction compared to lead-acid, preserving payload for water and supplies that extended dry camping requires.

These characteristics explain why serious dry campers increasingly specify LiFePO4 despite higher purchase prices.

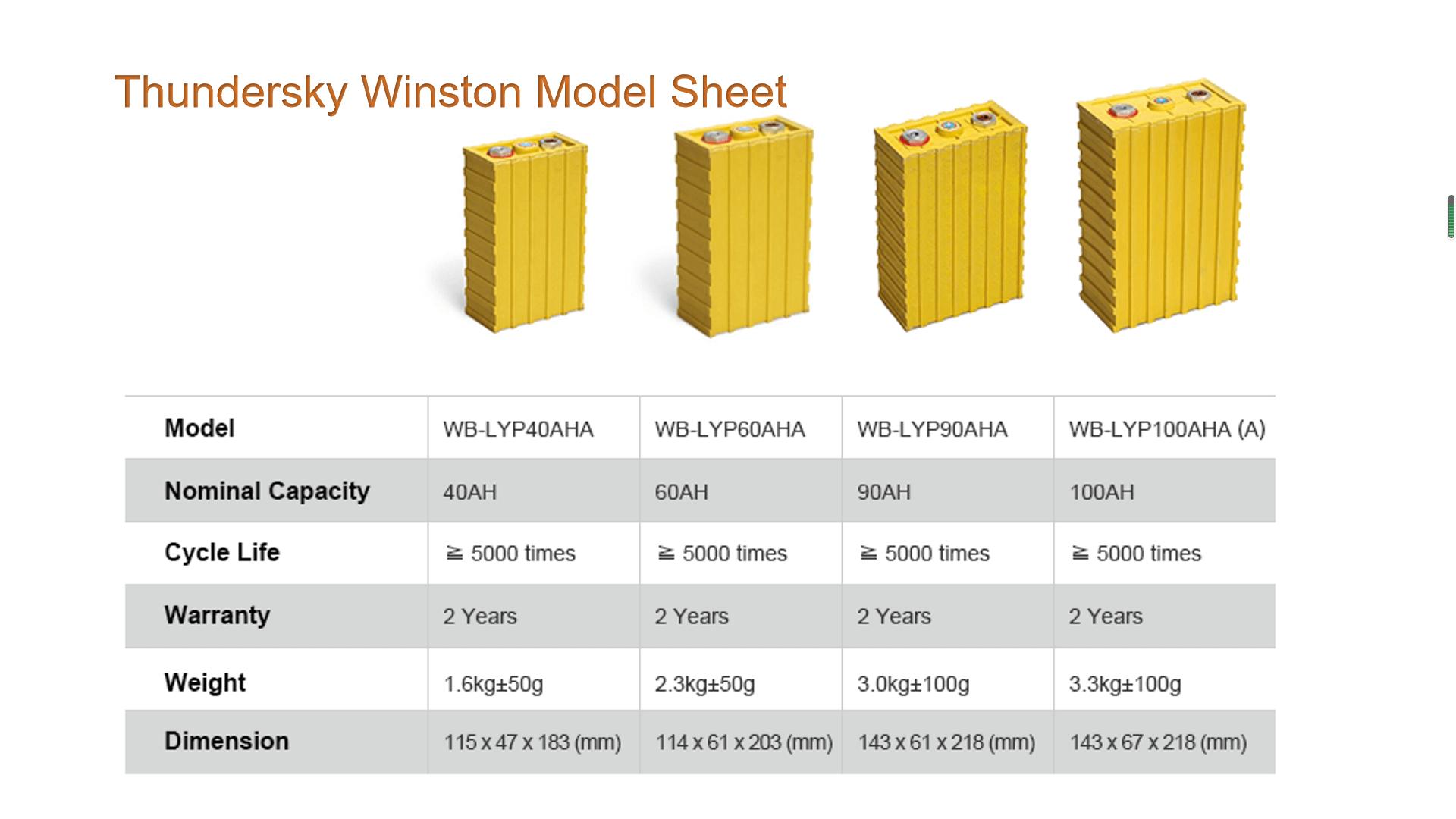

To explore a LiFePO4 solution designed specifically for sustained off-grid RV use, you can learn more about the Thunder Sky Winston 12.8V 100Ah battery by clicking here to view full specifications and application details.

RV battery installations present unique safety considerations. Batteries mount in enclosed compartments, sometimes inside living spaces or near LP systems. Occupants sleep feet from stored energy.

Standard LiFePO4 batteries provide significant safety improvement over older lithium chemistries, but thermal events remain possible under extreme conditions. Most require Class D fire suppression and can release gases during thermal breakdown.

Winston Battery's water-based LYP chemistry addresses RV-specific safety concerns(Why Winston Battery Prioritizes Safety-First Design):

Water-compatible suppression: Unlike standard lithium requiring specialized extinguishers, Winston batteries can be suppressed with water, equipment every RV carries.

Reduced toxic gas generation: Water-based cathode chemistry produces significantly less hydrogen fluoride during thermal events, a meaningful distinction in confined RV interiors.

Intrinsic thermal stability: The chemistry itself resists thermal runaway at the material level, independent of BMS protection circuits.

For RV applications where thermal events would create serious consequences far from emergency services, these safety characteristics justify evaluation beyond standard LiFePO4 options.

Extended boondocking: 4-7 days between charging

Seasonal dry camping: Consider worst-case scenarios

It is worth noting that Winston Battery originated from industrial and mission-critical applications, and its RV solutions are derived from those higher-risk design requirements rather than consumer optimization.

The best RV battery for dry camping matches your operational requirements rather than maximizing specifications or minimizing purchase price.

For occasional dry camping with moderate loads, standard LiFePO4 from reputable manufacturers delivers significant improvement over lead-acid at reasonable cost.

For extended off-grid operation, four-season use, or safety-priority installations, evaluation criteria shift toward deep discharge tolerance, wide temperature performance at the cell level, thermal safety in confined spaces, and predictable long-term degradation behavior (Cycle Life, Degradation, and Long-Term Service Design).

Winston Battery's water-based LYP chemistry illustrates how these criteria can be addressed through chemistry-level design rather than BMS protection alone.

The right battery decision starts with honestly assessing your operational pattern, duration targets, and environmental exposure, then selecting the chemistry and construction that match those realities.