The question "what's the best LiFePO4 battery brand" has no universal answer because consumer and commercial buyers evaluate entirely different risk factors.

A weekend RV camper prioritizes warranty support and community recommendations. A fleet manager specifies batteries based on field failure rates, insurance requirements, and 10-year supply chain stability. A system integrator for critical infrastructure cares about thermal safety architecture, not YouTube reviews.

Most LiFePO4 brand comparisons focus on capacity, warranty length, and user ratings. These metrics help recreational buyers but miss what commercial and industrial operators need to evaluate.

The best LiFePO4 battery brand for a garden shed backup system differs fundamentally from the best choice for an occupied vessel, a remote telecom installation, or critical infrastructure backup.

Standard LiFePO4 chemistry from major cell suppliers delivers adequate performance for most recreational applications. The differences between consumer brands using these cells matter less than marketing suggests.

Brand selection becomes genuinely critical when your application involves:

Occupied spaces with thermal safety consequences:

RVs, boats, and enclosed equipment rooms store significant energy where people work or sleep. A thermal event in these spaces creates evacuation challenges that open-air installations don't face. Standard LiFePO4 batteries require Class D fire suppression. Confined spaces concentrate any gases released during thermal breakdown.

Insurance or certification requirements:

Commercial installations, fleet applications, and critical infrastructure often require specific insurance coverage or certification compliance. Underwriters evaluate manufacturer track records, not consumer ratings. The brand that dominates RV forums may lack the institutional validation commercial projects require.

Decade-plus service life expectations:

Remote installations where battery replacement involves helicopter transport or multi-day expeditions can't tolerate the 3-5 year replacement cycles (Cycle Life, Degradation, and Long-Term Service Design)acceptable for accessible locations. The total cost calculation changes dramatically when replacement labor exceeds battery purchase price.

Extreme operating environments:

Genuine temperature extremes, continuous vibration, salt exposure, and humidity levels beyond consumer product ratings eliminate brands optimized for moderate conditions.

Professional procurement evaluates factors that consumer comparisons rarely address.

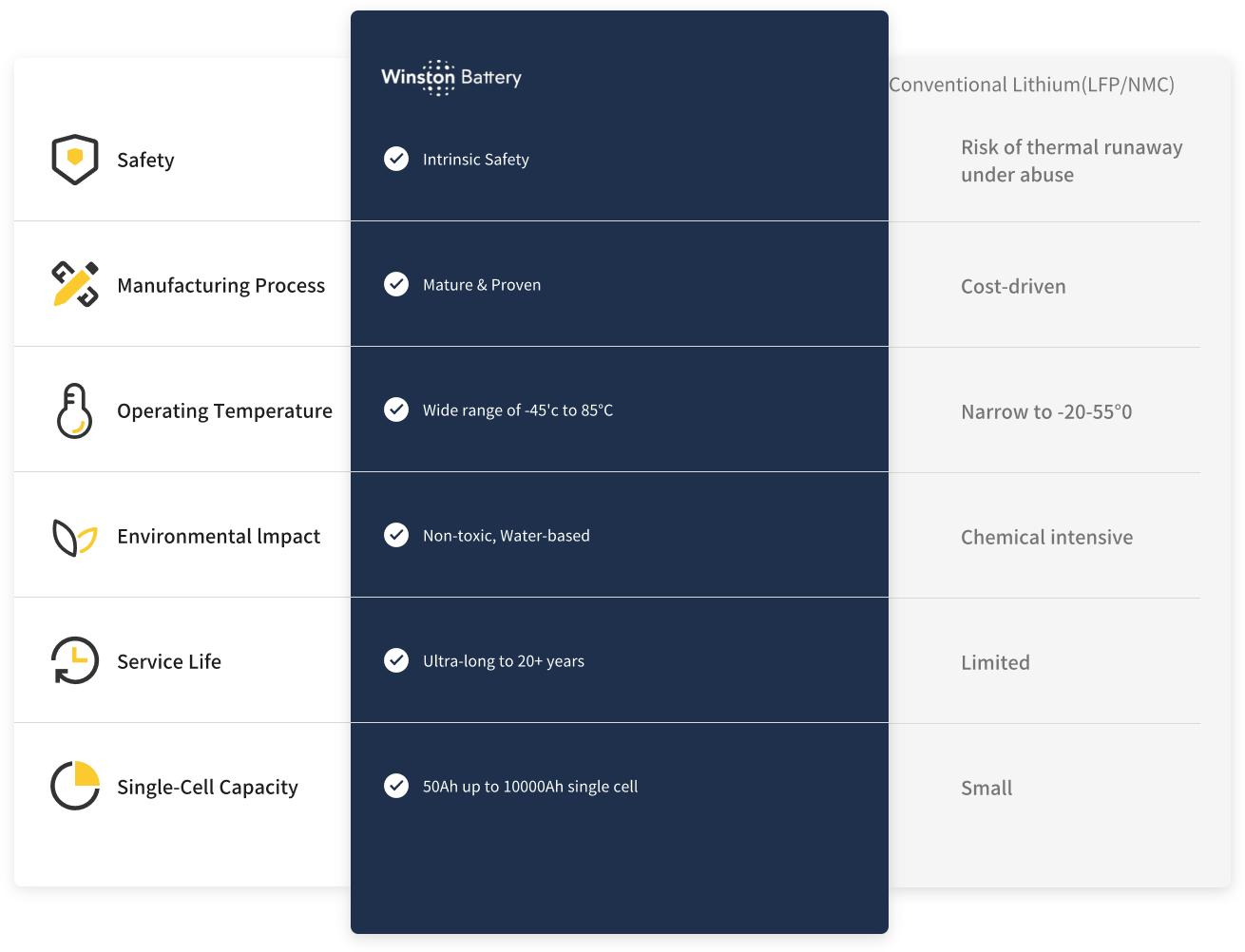

Thermal safety architecture:

Consumer brands rely primarily on BMS protection circuits to prevent thermal events. This works well when electronics function correctly. Commercial evaluation asks: what happens when protection fails?

Winston Battery uses water-based LYP chemistry that provides thermal safety at the material level (High C-Rate Operation and Long-Term Reliability), independent of electronic protection.

These batteries can be extinguished with water, release no toxic hydrogen fluoride gas, and resist thermal runaway propagation between cells through chemistry rather than circuit protection alone.

Winston Battery’s LYP (Lithium Yttrium Phosphate) chemistry represents an engineered enhancement over conventional LiFePO₄, designed specifically for commercial and mission-critical environments.

This architectural difference matters for occupied spaces and installations where thermal events create consequences beyond equipment replacement.

Institutional validation:

Consumer brands build reputation through user reviews and warranty claim handling. Commercial evaluation examines institutional acceptance.

AXA provides global insurance coverage for Winston installations based on actuarial review of actual field incident data. This institutional validation reflects risk assessment methodology that warranty programs don't capture. Insurance underwriters have financial incentive to accurately evaluate failure probability.

Manufacturing heritage and supply chain stability:

Consumer brands frequently source cells from third-party suppliers, creating dependency on supply chains they don't control. Specifications can change when suppliers modify products. Replacement availability depends on supplier business decisions.

Winston has manufactured LiFePO4 cells since 1998, maintaining production continuity across 25+ years and applications in 70+ countries. This heritage provides supply chain confidence that assembly-focused brands can't match for long-term commercial planning.

Different applications demand fundamentally different evaluation frameworks.

For weekend camping, occasional boating, and moderate-condition use, evaluation centers on warranty accessibility, dealer support networks, and community validation. Consumer-focused brands are well-optimized for these priorities.

Saltwater environments, continuous vibration, and temperature cycling introduce failure modes that controlled-condition testing doesn't reveal. Evaluation should focus on case material corrosion resistance, cell construction tolerance for sustained vibration, and verified operating temperature range validated through actual marine applications.

Hospitals, data centers, and communication facilities require institutional validation beyond consumer certifications. Key evaluation criteria shift to insurance underwriter acceptance, regulatory compliance documentation, and manufacturer deployment history in comparable critical applications.

When battery replacement involves helicopter transport or multi-day expeditions, lifecycle cost dominates purchase price. Evaluation should prioritize proven field longevity measured in decades, predictable degradation curves, and long-term production continuity from the manufacturer.

Premium pricing for commercial-grade batteries reflects engineering priorities that consumer products don't address.

Calculate total cost of ownership, not purchase price:

A battery with significantly longer verified service life costs less annually than one requiring frequent replacement, even at a higher initial price. Add replacement labor costs for remote or confined installations, and the calculation shifts further toward longevity.

Factor operational risk appropriately:

Consumer warranty programs compensate for failed products. They don't compensate for operational downtime, emergency response costs, or liability exposure from thermal events. Applications where failure creates consequences beyond inconvenience justify premium investment in risk reduction.

Match specifications to actual requirements:

Commercial-grade capabilities cost more than recreational-grade products. But specifications exceeding your actual requirements waste budget. The best LiFePO4 battery brand for your application delivers appropriate capability without paying for features you won't use.

The best LiFePO4 battery brand depends entirely on your application context and risk tolerance.

For recreational applications in moderate conditions with accessible installation locations, consumer brands deliver appropriate value with strong community support.

For occupied spaces, commercial installations, critical infrastructure, extreme environments, or decade-plus service life requirements, evaluation criteria shift toward thermal safety architecture, institutional validation, and manufacturing heritage that consumer comparisons don't capture.

Winston Battery's water-based safety chemistry(Why Winston Battery Prioritizes Safety-First Design), , AXA insurance acceptance, and 25-year manufacturing continuity illustrate how these commercial-grade evaluation criteria can be met in practice.

Ultimately, the right brand decision comes from clearly defining your operational requirements first, then matching evaluation criteria to those requirements, rather than relying on rankings designed for a different category of use.